By forcing more air into the combustion chamber, turbos have allowed engines to produce more power without significantly increasing their size. In 2000, only 1% of new cars manufactured in the US had turbos fitted, but by 2019 that number was over 33% - and it’s only increasing.

With the huge benefits they bring, it’s easy to see why turbos are becoming more prevalent. But even though they improve an engine’s efficiency and performance, there is one common issue that has likely been felt by most drivers: turbo lag. But what is turbo lag and how can you prevent it? In this article, we will explore turbo lag in detail and explain how you can reduce its impact on your driving.

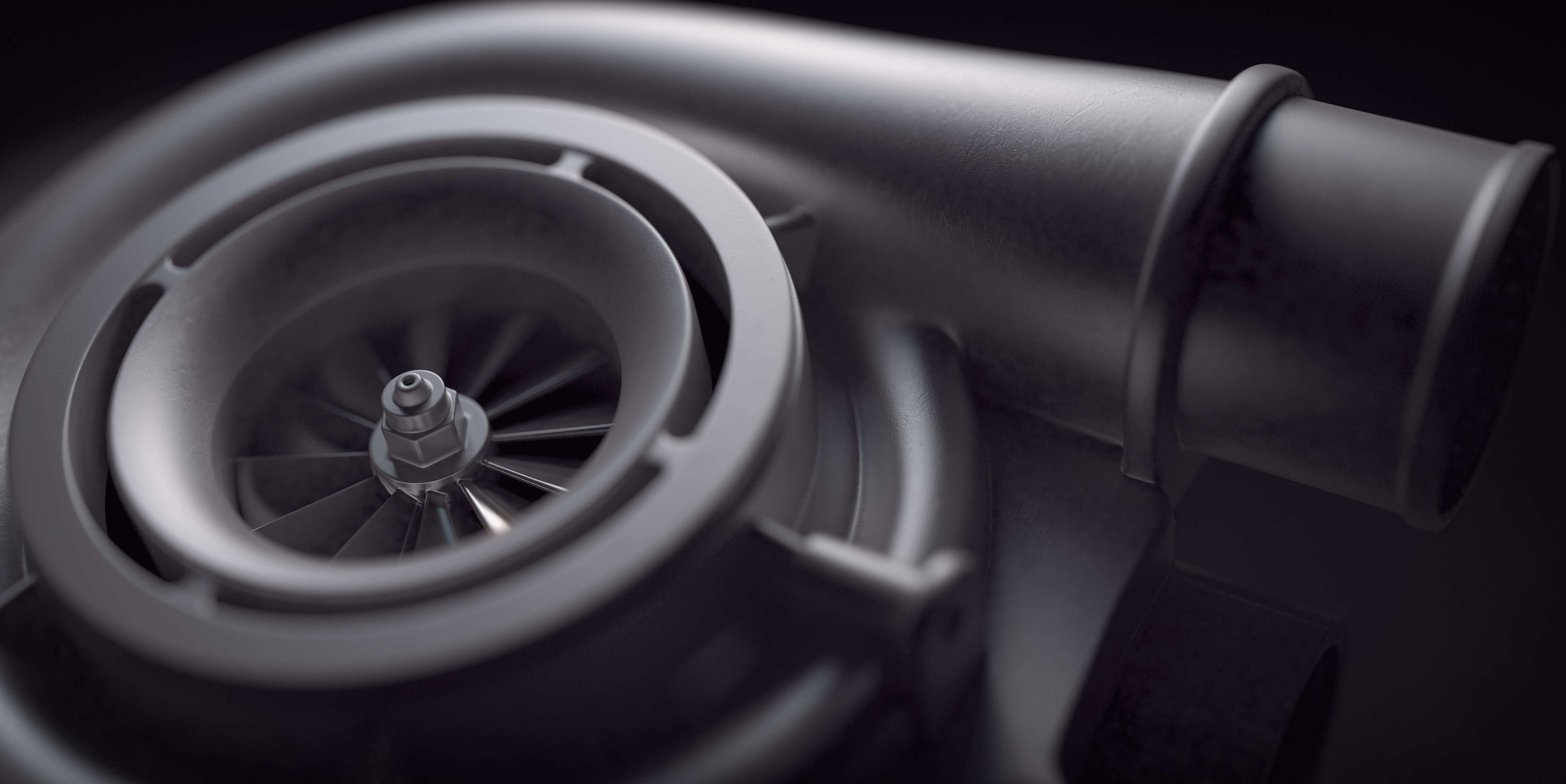

What is a turbocharger?

Before we dive deeper into turbo lag, we first need to understand what a turbocharger is and how it functions. A turbocharger is part of a vehicle that improves the efficiency and power of an internal combustion engine by forcing more air into the combustion chamber.

A turbocharger typically consists of two main parts: the turbine and the compressor, which are connected by a shaft. The turbine is powered by exhaust gases from the engine, which are used to drive the compressor. The compressor is attached to the turbine by a shaft and draws in air as the turbine turns and then converts the air into a high-pressure stream that's pushed into the engine.

The turbine and compressor wheels essentially work together to boost the intake air pressure of an internal combustion engine. That means that more fuel can be burned, and therefore power output is increased.

What is turbo lag?

In simple terms, turbo lag is the delay that occurs between pressing your vehicle’s accelerator and the turbocharger providing increased power. The reason this lag occurs is that it takes time for the exhaust gases to spin the turbine to a speed where it can effectively boost engine power. This delay can be felt by the driver and is often frustrating as you typically expect your vehicle to be immediately responsive to your inputs.

The issue is that turbochargers only activate at certain RPM ranges. So when pressing down on the throttle from idle, you won’t notice an immediate boost in torque. If you press the gas pedal further down, the engine will then provide a noticeable power boost. That delay is turbo lag, and it’s a normal part of having a car with a turbocharger.

Causes of turbo lag

Engines are incredibly complex bits of machinery, with lots of different components that must work together smoothly to create the desired output. Because turbochargers use waste energy from the engine as a form of power to work, they must be fully integrated into this fine-tuned system. No matter how harmoniously all the parts work together, turbo lag will still occur, but the amount of turbo lag that is created is dependent on several factors, such as:

Time delay

Turbochargers work by using the energy from exhaust gases to spin a turbine, which then compresses air into the engine to provide a boost. But in order for this process to work, the exhaust gases need to reach a certain speed and pressure to spin the turbine effectively. When you press down on the accelerator, there is a time delay before the exhaust gases build up enough energy to reach this point. The longer it takes for the exhaust gases to generate enough energy to spin the turbine, the longer the extra power delivery from the turbocharger will be delayed.

Inertia

Inertia is a scientific concept that refers to the resistance of any physical object to a change in its state. In simple terms, it means that objects in motion tend to stay in motion and objects at rest tend to stay at rest, unless some external force changes their state. The rotating components within a turbo when not operating have inertia that must be overcome to get them spinning. The greater the mass of these components, the longer it takes for them to work, contributing to turbo lag.

Air-fuel mixing

Once the turbocharger is operating, it compresses the intake air before feeding it into the engine. This denser air must then be mixed with fuel within the engine to achieve optimal combustion. There are three steps here that can lead to turbo lag: the air intake itself, the fuel injection process, and the actual mixing and combustion of the air-fuel mixture. Any delay in one of these steps can contribute to turbo lag.

Turbo design

The design of the turbocharger itself, as well as the exhaust manifold, and intercooler, are all vital when it comes to the efficiency of the system. For example, a larger turbo will be able to provide more boost, but it will also likely have more inertia and take longer work, creating more turbo lag. Likewise, where the turbo is placed within the vehicle will affect turbo lag. A longer distance between the exhaust manifold and the turbo means exhaust gases have further to travel, and therefore there will be more turbo lag.

Engine size

Turbos run on exhaust gases, and the size of the engine affects the volume and pressure of those gases. A larger engine will typically produce more exhaust gas volume, while smaller engines produce less. The fewer exhaust gases there are feeding the turbo, the longer it will take to make it spin. Likewise, a larger engine will generate more exhaust gases, which can help the turbo work more quickly. But this doesn’t mean turbo lag is eliminated. If a large engine is used with a large turbocharger, it might still experience significant lag because of the inertia of the larger turbo components.

Carbon build-up

Carbon deposits build up on various components of the turbocharger, including the turbine and compressor wheels, variable vanes, housing, and exhaust manifold, which can severely impact its performance. These deposits restrict airflow and exhaust gas flow, reducing the efficiency of the turbocharger and causing it to take longer to spool up, leading to turbo lag.

Carbon build-up on the turbine wheel can create an imbalance and slow down its rotation, further delaying the turbo's response time. Likewise, if carbon deposits affect the wastegate, causing it to stick or not seal properly, the turbo may struggle to build boost efficiently. When it comes to VGT turbos, carbon buildup on the variable vanes can cause massive lag. If the vanes get stuck in one position, the vehicle can become stuck in a high or low boost situation, making it essentially undrivable.

How to reduce turbo lag

The amount of turbo lag a vehicle produces is largely down to the engineering and manufacturing process, and has to do with precisely how the vehicle was designed. That said, you may notice that the turbo lag in your vehicle has gotten worse over time. Fortunately, there are a number of things you can do to reduce turbo lag, even if you have no mechanical knowledge whatsoever.

1. Watch your driving habits

It’s always better to gradually increase throttle pressure when accelerating, rather than flooring it instantly. This allows the turbo to spool up more smoothly. Similarly, the turbo has an optimal RPM range for working efficiently, so downshifting to a lower gear before accelerating can help to keep the turbo spooled up and ready to operate.

2. Regular engine maintenance

In order for your car to run smoothly, its parts need to be in the best condition they can be. You want to ensure the air filters are clean so that airflow is not restricted. Likewise, you want to make sure the intercooler is clean and free from any debris as this can reduce its cooling efficiency. This can be achieved easily with regular servicing.

3. Use high-quality fuel

Whether you have a gas or a diesel vehicle, ensuring you are using the highest quality fuel can help improve combustion efficiency, and this can reduce turbo lag. For diesel fuel, you want to ensure you have the highest cetane rating possible. Unfortunately, due to low regulatory standards, diesel fuel in the US is of poor quality. Fortunately, you can boost your cetane rating by up to 8 points by using Archoil’s AR6500 Diesel Treatment every time you fill up.

4. Clean your fuel system

If you’ve noticed the problem of turbo lag getting worse, it’s likely a dirty fuel system is contributing to the problem. One of the easiest and most cost-effective ways to reduce this kind of turbo lag is to use fuel additives. Archoil’s Diesel Fuel System Kit has everything you need to clean your entire fuel system, including the fuel injectors, turbo, and DPF. By removing the build-up of carbon and soot from these components, particularly the turbo, you’ll be able to reduce the problem of turbo lag back to its factory condition.

5. Upgrade software (performance tuning)

Many modern vehicles can have their software altered to optimize turbocharger performance. This does require a visit to a professional, but the process can be as simple as installing a software update to optimize fuel and air delivery. We advise that you always speak to a professional before changing your vehicle’s software as there could be unintended consequences of changing parameters without a proper understanding of the vehicle.

6. Weight reduction

It’s not going to completely fix your turbo lag issues, but removing unnecessary weight from the car can improve overall performance and reduce the strain on the turbo, helping it to spool up faster. It ties into our earlier point about inertia, the more mass there is, the more energy that is required to move that mass.

How to get rid of or eliminate turbo lag

So you’ve read our tips on how to reduce turbo lag, but you might be thinking “That’s great, but how can I get rid of or eliminate turbo lag altogether? Well, the short answer is: you need to buy a new car. If you currently have a vehicle that suffers from bad turbo lag, using our diesel fuel additive to reduce turbo lag is your best option, but it will never improve beyond how it was when the vehicle was manufactured. The only way to get rid of turbo lag is to buy a new car that uses various technologies to get rid of or mask the problem.

Modern cars do still have a problem with turbo lag, but advances in design and engineering mean that it is now almost imperceptible to drivers. So what are the modern methods used to eliminate turbo lag? Read on to learn how engineers have essentially solved the turbo lag problem.

Using lighter materials

Manufacturers use lighter materials that are both lighter and stronger than older materials to help reduce inertia and air resistance, meaning that the turbocharger can spool up more quickly, and turbo lag is reduced.

Refining components

Engineers are constantly looking for ways to refine the designs of their components, improving efficiency, responsiveness, and performance. All parts of the turbo, such as the turbine, compressor, and even the bearings are constantly being iterated upon to reduce friction and inertia.

Electric turbochargers

More modern vehicles use electric turbochargers to spin the regular turbo up to speed before exhaust gases take over. By doing this, turbo lag is almost eliminated as the turbine in the turbocharger can operate without the need for gases.

Twin turbos

Another way to get rid of turbo lag is to use a twin-turbo setup. Essentially, two turbos are used. A smaller turbo works in lower RPM ranges, while a second, larger turbo takes over at higher RPM ranges. The downside is that sequential systems are more complicated and expensive than using an electric system.

Is my turbo working correctly?

We’ve discussed many factors that lead to turbo lag and some ways that you can fix them. But one thing we haven’t touched on is that your turbocharger could be lagging because of a malfunction or failure in the part itself. If you notice the turbo lag getting suddenly worse then it is likely to be a mechanical fault. These are some of the symptoms you might notice if your vehicle has a defective turbocharger:

- Excessive smoke

- Unusual noise

- Oil leaks

- Inconsistent boost pressure

- Too high exhaust gas temperature

- A smell of burnt oil from the exhaust

If you suddenly experience any of the above symptoms, you should have your car inspected by a professional as soon as possible. Ignoring these problems could lead to a catastrophic failure of your vehicle.

Conclusion

Turbo lag can be frustrating, but by using Archoil’s Diesel Fuel System Kit you can ensure your turbo is operating as close to the manufacturer’s design as possible. By using just these two products you can ensure your entire fuel system is running as smoothly as possible, extending its lifespan and potentially saving you a lot of money in the long run.

If you’re interested in learning more great tips to get the most out of your vehicle, you should take a look at our resources page. We’ve got guides on everything from diesel fuel to car maintenance on our Resources page.